Bobcat 337 Service Manual

Description Revised Factory Workshop Repair Service Manual Bobcat 337 341. Detailed Step by Step Instructions, diagrams, illustrations make easy any repair, Overhaul, Disassembly and Assembly, Testing, Adjustment, Replacement and Change, Inspection and Adjustment, etc.

This is the Highly Detailed factory service repair manual for theBOBCAT 337 COMPACT EXCAVATOR, this Service Manual has detailed illustrations as well as step by step instructions,It is 100 percents complete and intact. They are specifically written for the do-it-yourself-er as well as the experienced mechanic.BOBCAT 337 COMPACT EXCAVATOR Service Repair Workshop Manual provides step-by-step instructions based on the complete dis-assembly of the machine. It is this level of detail, along with hundreds of photos and illustrations, that guide the reader through each service and repair procedure. Complete download comes in pdf format which can work under all PC based windows operating system and Mac also, All pages are printable.

Using this repair manual is an inexpensive way to keep your vehicle working properly. Service Repair Manual Covers: Safety and maintenance Hydraulic system Undercarriage Upperstructure & swing section Electrical system and analysis Engine service Heating, ventilation, air conditioning Specifications File Format: PDF Compatible: All Versions of Windows & Mac Language: English Requirements: Adobe PDF Reader NO waiting, Buy from responsible seller and get INSTANT DOWNLOAD, Without wasting your hard-owned money on uncertainty or surprise! All pages are is great to haveBOBCAT 337 COMPACT EXCAVATOR Service Repair Workshop Manual. Looking for some other Service Repair Manual,please check: Thanks for visiting!

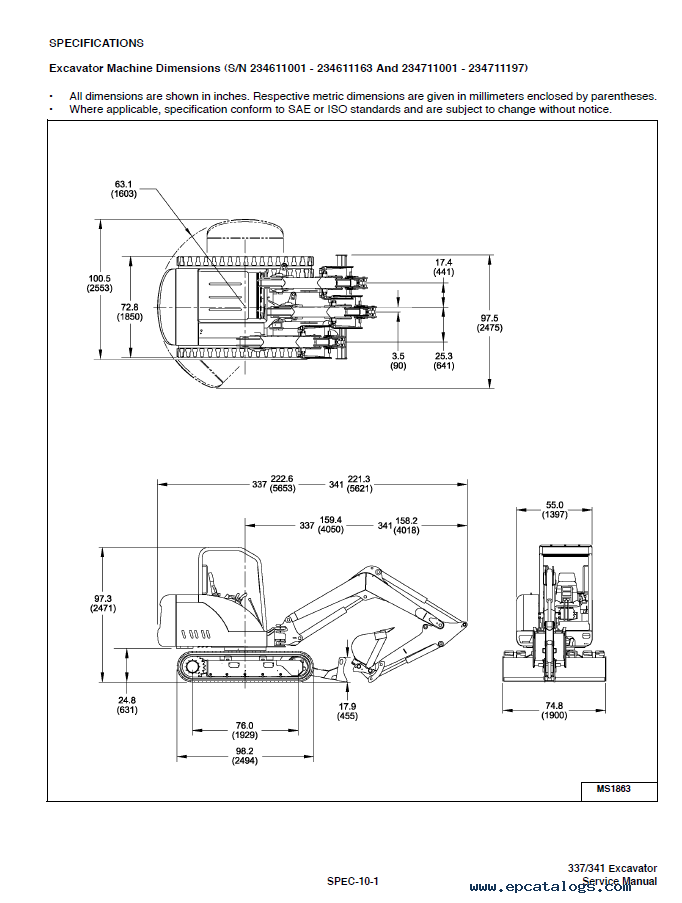

BOBCAT 337 COMPACT EXCAVATOR Service Repair Manual S/N 234611001 & Above. 1. Service Manual ©Bobcat Company 1 (11-07) 337 341 Printed in U.S.A. 337 - S/N 234611001 & Above 341 - S/N 234711001 & Above (G Series). MAINTENANCE SAFETY Never service the Bobcat Compact Excavator without instructions. Have good ventilation when welding or grinding painted parts. Wear dust mask when grinding painted parts.

Toxic dust and gas can be produced. Stop, cool and clean engine of flammable materials before checking fluids. Willys jeep driving manual. Never service or adjust machine with the engine running unless instructed to do so in the manual. Avoid contact with leaking hydraulic fluid or diesel fuel under pressure. It can penetrate the skin or eyes. Never fill fuel tank with engine running, while smoking, or when near open flame. Always lower the bucket and blade to the ground before doing any maintenance.

Never modify equipment or add attachments not approved by Bobcat Company. Keep body, jewelry and clothing away from moving parts, electrical contact, hot parts and exhaust.

Bobcat 337 Service Manual

Wear eye protection to guard from battery acid, compressed springs, fluids under pressure and flying debris when engines are running or tools are used. Use eye protections approved for type of welding. Keep tailgate closed except for service. Close and latch tailgate before operating the excavator. Vent exhaust to outside when engine must be run for service. Exhaust system must be tightly sealed.

Exhaust fumes can kill without warning. Cleaning and maintenance are required daily.

MSW28-0805 Use the correct procedure to lift and support the excavator. Lead-acid batteries produce flammable and explosive gases. Keep arcs, sparks, flames and lighted tobacco away from batteries. Batteries contain acid which burns eyes or skin on contact. Wear protective clothing.

If acid contacts body, flush well with water. For eye contact flush well and get immediate medical attention. WARNING Instructions are necessary before operating or servicing machine.

Read and understand the Operation & Maintenance Manual, Operator’s Handbook and signs (decals) on machine. Follow warnings and instructions in the manuals when making repairs, adjustments or servicing.

Check for correct function after adjustments, repairs or service. Untrained operators and failure to follow instructions can cause injury or death. W-2003-0903 Maintenance procedures which are given in the Operation & Maintenance Manual can be performed by the owner/ operator without any specific technical training. Maintenance procedures which are not in the Operation & Maintenance Manual must be performed ONLY BY QUALIFIED BOBCAT SERVICE PERSONNEL. Always use genuine Bobcat replacement parts.

The Service Safety Training Course is available from your Bobcat dealer. Safety Alert Symbol: This symbol with a warning statement, means: “Warning, be alert! Your safety is involved!” Carefully read the message that follows. B-10731A CORRECT B-19964 CORRECT CORRECT B-19959 B-19965 WRONG WRONG B-19960 B-19966 WRONG WRONG B-19962 B-19958 WRONG B-19798 WRONG. 337/341 Excavator Service Manual ALPHABETICAL INDEX AIR CLEANER.

10-01, 60-01 AIR CONDITIONING SERVICE. 70-01 AIR CONDITIONING SYSTEM FLOW. 70-01 ALTERNATOR. 50-01 ARM. 40-01 ARM CYLINDER. 20-01 BASIC TROUBLESHOOTING.

70-01 BATTERY. 50-01 BLADE. 30-01 BLADE CONTROL. 40-01 BLADE CYLINDER. 20-01 BOOM.

40-01 BOOM CYLINDER. 20-01 BOOM SWING CYLINDER. 20-01 BOOM SWING LOCK VALVE. 20-01 BUCKET. 40-01 BUCKET CYLINDER. 20-01 BUILD UP VALVE.

20-01 CAB. 40-01 CASE DRAIN FILTER MOUNT.

20-01 CLAMP CYLINDER. 20-01 COMPONENTS. 70-01 COMPRESSOR. 70-01 CONDENSOR. 70-01 CONTROL LINKAGE ASSEMBLY.

40-01 CONTROL PATTERN SELECTOR VALVE. 20-01 CONVERSIONS.SPEC-01 COOLING SYSTEM. 10-01 CROSSPORT RELIEF VALVE. 20-01 DELUXE INSTRUMENT PANEL SETUP. 50-01 DIAGNOSTICS SERVICE CODE. 50-01 DIRECT TO TANK VALVE.

20-01 DUAL SEQUENCE VALVE. 20-01 ELECTRICAL SYSTEM INFORMATION. 50-01 ENGINE. 60-01 ENGINE ACCESSORY DRIVE BELT. 10-01 ENGINE COMPONENTS AND TESTING. 60-01 ENGINE FLYWHEEL.

60-01 ENGINE LUBRICATION SYSTEM. 10-01 ENGINE SPECIFICATIONS.SPEC-01 ENGINE SPEED CONTROL. 40-01 EVAPORATOR. 70-01 EVAPORATOR/HEATER UNIT.70-01 EXPANSION VALVE.70-01 FLOORMAT AND FLOOR PLATE.40-01 FUEL, COOLANT AND LUBRICANTS.

SPEC-01 FUEL LEVEL SENDER.50-01 FUEL SYSTEM.10-01 FUEL TANK.40-01 GENERAL AIR CONDITIONING SERVICE GUIDELINES.70-01 HEATER/AC FAN.70-01 HEATER AIR FILTER.10-01 HEATER COIL.70-01 HEATER VALVE.70-01 HORN.40-01 HYDRAULIC CONNECTION SPECIFICATIONS. SPEC-01 HYDRAULIC CONTROL VALVE.20-01 HYDRAULIC FILTER MOUNT.20-01 HYDRAULIC FLUID SPECIFICATIONS.

Top Articles

- ✔ 1989 Honda Civic Lx Service Manual

- ✔ Manual For A Bobcat 443

- ✔ Repair Manual For Chevrolet Optra

- ✔ 2018 Gmc Sierra Fuel Pump Replacement Manual

- ✔ Conceptual Physics 11th Edition Study Guide

- ✔ Wechsler Individual Achievement Test Iii Technical Manual

- ✔ Revit Structure 2016 User Guide Bing

- ✔ 2015 Mercury Optimax 200 Manual

- ✔ Repair Manual Jeep Commander 06

- ✔ Vault Guide To Investment Banking 2012

- ✔ 2018 Lincoln Continental Service Manual

- ✔ Sea Survival A Manual Dougal Robertson

- ✔ Polaris Ranger 400 Owners Manual

- ✔ 333 Planter Manual

- ✔ Echo Cls 4600 Manual

- ✔ 4g15 Manual Upgrade Engine

- ✔ Mitsubishi Pajero 2003 Manual

- ✔ Mustang Haynes Repair Manual

- ✔ Yamaha Wolverine 350 4x4 2018 Service Manual

- ✔ Manger Cosmetology Ohio State Board Study Guide

- ✔ Review Study Guide For Plumber Apprentice Test

- ✔ Lexus Rses Service Manual

- ✔ 2016 Kawasaki 610 Mule Service Manual