Vendo Vr12 Manual

Keeping your commercial refrigeration system continuously operating is a high priority for you and your customers. Must be kept in prime condition in order to ensure food is safe for consumption, prevent food spoilage and maintain consumer satisfaction. A well maintained cooler also helps reduce energy costs and lessen environmental impact. Imbera Services is the technical assistance branch of Imbera Foodservice.

We’re the largest commercial refrigeration service provider in the Americas. Our team of 2,500 refrigeration specialists service over 1.3 million coolers every year.

Imbera offers easy-to-order spare parts and accessories for any commercial refrigeration system. Imbera provides technical assistance, technician training & troubleshooting for our customers and a comprehensive warranty program through our service contractor network throughout the United States & Canada. Our Warranty Service & Technical Support Warranty Policy Our warranty policy is designed to protect our customers against any manufacturing defects in components and issues that result from the manufacturing process. Units will be repaired or replaced at no cost to the customer, provided units are operated and installed under the specific usage conditions designed for each model as outlined by Imbera User Manuals.

Our warranty includes parts, standard ground freight and labor performed at time of service. It also includes supplemental materials such as refrigerant gas, filter drier, welding, etc. Whole Cooler: 3 year warranty.

Compressor: 5 year warranty (First 3 years – labor & parts. Additional 2 years – compressor parts only.) Installation and Relocation We make sure that the equipment will not be damaged during transport and that it is properly installed for optimal performance.

Our comprehensive service includes:. Transportation of equipment to the point-of-sale. Preparation for installation.

Review of electrical installations and the proper operation of the equipment. Shelving and accessories installation. Product marketing.

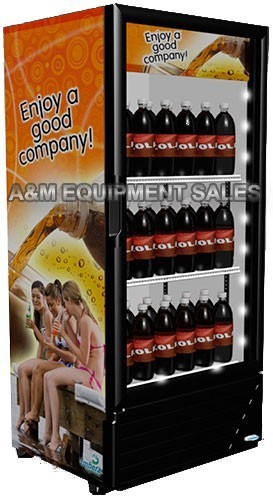

Explanation of the use and care of equipment. Removal from the point-of-sale Equipment Upgrade We have developed several alternatives for upgrading traditional commercial refrigeration equipment from different brands to make them more efficient. We use the latest technology to improve the visual appeal, operation and energy performance of your refrigeration system.

Upgrade options include:. Painting on shelves, door and crested framework.

Change to plastic louver to facilitate ventilation with increased durability. Implementing Energy Management & Maintenance Devices (EMMD). Switching to LED lighting to lower energy consumption. Installing electronic motors Scheduled Maintenance Regular maintenance of your commercial refrigeration system extends its life cycle, reduces energy consumption and increases the unit’s appeal at the point-of-sale.

A consistent maintenance program includes repair, retrofitting, technological upgrades and visual improvements to commercial refrigeration systems. Our maintenance services include:.

Fumigation. Cleaning. General Check-up.

Imbera Vr12 Manual

Operational Repairs. Body and Painting. Image Replacement. Technological Upgrades.

Quality Control Contact us to set up a scheduled maintenance program for your commercial refrigeration equipment. Service Calls We respond in a timely manner to service requests. This is reflected in the short response times we provide to our customers. We have robust information and control systems that allow us to provide prompt, data-driven service. This ensures that your coolers remain in good working order. Our field technicians come to your location and follow these steps to fix your cooler:.

Diagnosis. Your technician finds the source of your problem. Error Correction. Your technician fixes the problem. Cleaning & Adjustment of Components. While we are fixing your cooler, we perform any necessary preventative maintenance to ensure your system continues to operate at peak performance. Verification of Operating Conditions.

We review your system’s operations to verify that your cooler is in perfect working condition. Usage Recommendations.

Your technician will share useful tips with you about how to care for your cooler and keep it in optimal working capacity. Final Disposal Once your equipment has reached the end of its life cycle, perform the final disposal of equipment in compliance with environmental regulations such as NOM-052-ECOL and NOM-058-SEMARNAT. We also recoup as many parts as possible from units so the can be reused.

These steps help us to reduce the environmental impact of our commercial refrigeration systems. Technical Support Contact Information Imbera Services highly skilled and experienced team of professionals stands ready to assist you. Contact the team member in your region with your commercial refrigeration maintenance, repair and warranty needs.

Vendo Manuals The following documents are parts and service manuals for Vendo vending equipment. The manuals below are in PDF form and download times may vary. All trademarks and copyrights on this page are owned by their respective owners.

Vendors Exchange® does not hold responsibility for the correctness of these manuals. Please refer back to Vendo for the most up to date and accurate information about these machines. Click on each link for a downloadable PDF. Vendo Manuals. Vendo Set-Up Guides.

Top Articles

- ✔ Fishes And Amphibians Study Guide

- ✔ Clarkson Miller Cross Business Law Study Guide

- ✔ Fanuc 18m Programming Manual

- ✔ Repair Manual F700

- ✔ Manual Water Pressure Pump Mercury 150 Hp

- ✔ Visual Basic 2016 Solution Manual Zak

- ✔ Grade 11 Physics Lab Manual 2018

- ✔ 2018 Chevrolet Cavalier Haynes Repair Manual

- ✔ Gmc Yukon Xl 2016 Service Manual

- ✔ Tax Guide 2017 South Africa

- ✔ Free Sda Minister Manual

- ✔ Bladez Xtr Manual

- ✔ Stihl Fs 83 Parts Manual

- ✔ Construction Site Safety Manual

- ✔ Someone Named Eva Study Guide

- ✔ Singer Sewing Machine Service Manual 112w 140

- ✔ Pennzoil Lubrication Recommendation And Capacities Guide

- ✔ Eoc World History Study Guide

- ✔ Kubota G5200 Manual

- ✔ Introduction Management Accounting 15th Edition Solution Manual

- ✔ Thermo King Manuals Kv 300 Ii

- ✔ 2016 Jeep Grand Cherokee Lift Guide

- ✔ E320 Cdi Repair Manual

- ✔ Palomino Truck Camper Manual